Introduction

CAD role in the medical implant industry

Medical implants are crucial in curing or providing relief for various types of maladies and physical difficulties. For example, the artificial pacemaker is used for patients with heart problems. In case of the patient requiring a hip joint replacement, the surgery must be conducted needing a prosthetic implant for the patient. Similarly, for serious knee injury or other degenerative conditions, replacement of patella through knee surgery may be necessitated. This necessity of various types of medical implants has given rise to an entire industry of designing and manufacturing optimum quality medical implants. CAD system has been instrumental in designing implants that can be manufactured and provide improved medical care. Inputs to these CAD designs, the measurements, and orientation, are either captured manually by the design engineer or provided externally by another system. That is, the varying needs of the different patients would neither be identified nor be addressed optimally. CAD Automation can prove to be helpful in interpreting the different measurements and orientations in this context. It is all about accurately determining how the implant would be built and the ways it would be positioned within the patient’s body.

CAD Design Automation Role in the Making of Custom Implants

Radiological Imaging techniques like X-Ray, CT, MRI, Fluoroscopy, etc. along with clinical co-relations helps in identifying the patient-specific needs of an implant. Medical imaging data can be integrated into the CAD design automation system through a specialized custom module which should also have provision to capture mandatory clinical parameters to be considered. The information thus gathered is to be fed into a specialized medical software infrastructure for analysing and enumerating appropriate design parameters. Then there is the crucial and active role of a CAD application, which would be utilized to do the designing tasks with custom positioning and manufacturing measurements that are case-specific.

Explanation with an example

In a case study example, researchers Jitesh Madhavi and Jayesh Dange have shown how CAD modelling can actually elucidate the anatomical structure and automate the calculations with regard to material density and orientation of the implant in question. This case study began with one patient who had a large defect as lower femur fracture. He had to be given individual prostheses for reconstruction. Necessary patient data were obtained through MRI along with consistent management of both the acquisition factors and the reconstruction factors. This was followed by automated 3D geometric reconstruction. The lessening of bone density pixels gave away basic data meant to represent the structure, contour, positioning, and orientation of bony structures. Using automation, scan reconstruction data was converted into 3D contour models.

Initial Graphics Exchange Specification or IGES format defines a neutral data format that facilitated design automation by ensuring interoperability with the CAD system which converts the surface to a solid model.CAD system by CAD development companies was also used for Surface cleaning and stitching gaps with new surfaces. Cumulatively, the replacement implant for the lower femur fracture under investigation was patient-specifically built with the help of custom measurements being materialized through CAD product development designing, interoperation, and finally, manufacturing for the correct orientations.

The Rise in Need of Custom Implants

Importance of Custom-Designed Implants

In the 21st century, when more surgical options are becoming available due to the advancement of medical science, the medical implant industry is expanding every day. While long-lasting patient comfort is a crucial part of any kind of implant surgeries, accurate placement of prosthetic implants (of hips, knees, etc.) is crucial to reduce the risk of discomposure and the necessity for expensive revision surgeries. Thus, the production of custom-designed medical implants coupled with radiological imaging techniques and three-dimensional simulations has become a field of growing significance. Custom-design development enables a multitude of implant variations as well as pathologies to be considered at the very virtual stage with the help of simulation and an additive manufacturing approach. This kind of process engineering is counterpoised to discovering and researching postsurgical issues by the means of cumbersome trial and error techniques.

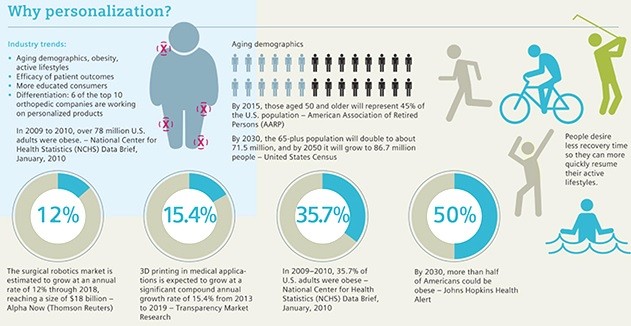

Custom Designed Implant reduces the risk of future dislocation by increasing the accurateness and trustworthiness of medical implants. The importance of customization in medical implants technology is explained in the diagram below (Courtesy Innovative Publishing Co. LLC). It also shows that the number of people aged above 65 years would soon increase to 71.5 million by the year 2030. Such a large population of older adults is projected to increase the cumulative demand for replacement surgeries too. Hence, the key designing processes should not only be streamlined but made faster too.

Importance of Patient-Centric Implants

Design automation for custom implants design

Increasing the speed of on-demand production requires that at least some parts of the implant design manufacturing process in question must be automated. CAD software packages by CAD customization services play an important role in automation with respect to the all-crucial patient-centric and customizable design processes. The mission-critical design techniques, as described by the manufacturer’s methodological algorithms for surgery, implant positioning, and sizing, would make use of biomechanical axes and anatomical hyper points which can be detected on three-dimensional volumetric models that are likely to vary from one patient to another. CAD software can indeed automate several steps in this complicated design workflow with the help of customizable templates and programmed scripts. In this way, automation is targeted to make the three-dimensional positioning, sizing, and shaping of patient-specific implants a rapid, accurate, and exceedingly repeatable process.

Conclusion

In exploring how CAD software development is impacting the medical implants industry, it is necessary to point out that there have been multiple failures in joint replacement and implant surgeries. With the help of CAD, rapid designing in accordance with patient-specific variations in measurements and orientations has become possible. To summarize, it can be stated that data acquisition and interoperability across software applications (Medical and CAD) are a prime requisite before implementing automation for designing and manufacturing patient-centric implants. Furthermore, the availability of skilled resources to develop the integration and automation modules in the field is another imperative. Rest assured CAD automation is not only helpful in building patient-centric implants but also handy for decreasing production time for the implants significantly.