Additive manufacturing witnessed tremendous growth and popularity in the early 2000s, and this technology was believed to revolutionize personalization for the mass market. Over 20 years later, the reality is not far from what was initially thought.

The rising incidence of chronic disorders and the increasing demand for customized medical devices like implants have fuelled the growth of the healthcare additive manufacturing market. The global market for healthcare additive manufacturing was valued at $2.80 billion in 2022 and is projected to reach approximately $15.35 billion by 2032.

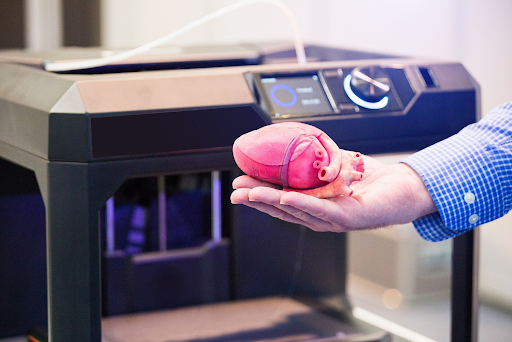

This growth is particularly pronounced in specialized medical applications, where various medical additive manufacturing techniques play a pivotal role. These techniques are used to create medical models, implants, tools, parts for medical devices, medical aids, guides, splints, prostheses, and biomanufacturing.

This growth is particularly pronounced in specialized medical applications, where various medical additive manufacturing techniques play a pivotal role. These techniques are used to create medical models, implants, tools, parts for medical devices, medical aids, guides, splints, prostheses, and biomanufacturing.

According to the 3D Printed Medical Devices Global Market Report 2023, the 3D-printed medical devices market is expected to reach $9.09 billion by 2027, further highlighting the growing relevance of additive manufacturing for healthcare.

But what does the future of additive manufacturing look like? Let’s take a look at what lies ahead for the industry.

Additive Manufacturing in the Healthcare Industry: A Comprehensive Perspective

- Patient-specific Personalization

In the medical field, each patient is unique, which is why additive manufacturing for medical devices has great potential for personalized and customized medical applications. Additive manufacturing (AM) technology allows medical devices to be tailored to individual patients’ anatomical requirements, enhancing their efficacy and comfort.

- Creation of Complex Designs

Another notable feat in additive manufacturing is the ability to construct complex designs and structures. With traditional manufacturing processes, intricate geometrical shapes were often challenging or impossible to fabricate. On the other hand, additive manufacturing builds objects layer by layer, enabling the creation of devices with complex internal structures that can improve device performance.

- Use of Biocompatible Materials

Additive manufacturing uses a wide range of biocompatible materials. This includes metals, ceramics, and polymers, many of which can be processed into a biocompatible form suitable for patient contact. These materials can be fine-tuned to achieve the desired mechanical properties, degradation rates, or other needed specifications, opening new horizons in the design and manufacture of medical devices.

Experience state-of-the-art digital and engineering services designed for superior medical devices and diagnostics.

Challenges and Solutions in Additive Manufacturing for Healthcare

While additive manufacturing offers numerous possibilities for healthcare, it faces a few challenges.

- Regulatory and Quality Control Issues

The healthcare sector is highly regulated to ensure safety and efficacy. The challenge lies in establishing quality control standards for 3D printed objects due to their novelty and the variability in the printing process. One solution is to develop international standards and use advanced technologies like machine learning to ensure quality.

- Material Limitations

The materials used in 3D printing must meet strict biocompatibility, durability, and functionality requirements. Currently, there are limited options for medical-grade materials. Ongoing research aims to discover and evaluate new biocompatible materials for additive manufacturing for medical devices.

- Technological Constraints

Current 3D printing technology struggles to create complex and precise objects for various medical applications. Additionally, production speed may not meet urgent medical needs. Advancements in AM technology, such as higher-resolution printers and faster printing techniques, can be potential solutions to these issues.

Now, what is the future potential of additive manufacturing in healthcare?

According to Forbes, 3D printing is one of the top ten future trends in the manufacturing industry. In healthcare, 3D printing is already being used to produce medical devices. As more companies adopt this technology, its advancement and popularity will only increase.

AI & Machine Learning in Additive Manufacturing

AI and machine learning, when combined with additive manufacturing, can revolutionize the healthcare industry. These technologies can simplify the design process, optimize material usage, and improve production efficiency. They can also help identify and predict potential errors or defects in 3D printed products before printing, reducing waste and saving time.

Advancements in Materials and Techniques

As additive manufacturing technology advances, there are significant developments in new materials and improved techniques. Researchers are focusing on creating biocompatible materials that can seamlessly integrate with the human body. Techniques like selective laser sintering and direct metal laser sintering facilitate the production of more intricate and robust structures.

More 3D Printed Implants and Prosthetics

The use of 3D printing for implants and prosthetics is gaining popularity. Tailored specifically to each patient’s anatomy and requirements, these customized prosthetics and implants can be created with exceptional precision and speed. This enhances patient outcomes and reduces costs compared to traditional manufacturing methods. As technology advances, we can anticipate widespread demand and adoption of 3D-printed medical devices soon.

Conclusion

The combination of additive manufacturing and computer-aided design is paving the way for a future in healthcare where customized treatment is the norm. Companies can produce implants and devices tailored to individual patients, resulting in better treatment outcomes.

Unlike traditional manufacturing, additive manufacturing allows for intricate designs and shapes that were previously impossible. In particular, CAD design automation simplifies the creation of custom implants for pre-surgical planning. As the global market for medical devices grows, the future of additive manufacturing looks promising and paves the way for personalized medical devices.

Our offerings to the medical devices and diagnostics industry (MDDI) cover product engineering, manufacturing, compliance, and after-sale services to ensure improved prod uct performance, functionality, and user experience.

At CADVision, we leverage the latest technology advancements and industry expertise to enhance designs, minimize material waste, and provide cost-effective solutions for our clients.

Popular Posts

- What Are the 5 Key Aspects of Medical Device Design?by Admin

- Latest Trends in Design Process Automationby Admin

- Generative AI Revolutionizing Medical Device Innovationby Admin

- How to Design & Develop Custom-Specific Implantsby Admin

- Key Considerations for Planning a Successful Design Process Automation Strategyby Admin

Categories

Tags

3D printing help in the medical field Automation in CAD data migration Business CAD customization services CAD data migration benefits CAD data migration methods CAD data migration planning CAD design automation CAD Design Automation In Medical Implants CAD development services CAD for Medical Device Design CAD Software CAD software development CAD software development companies CAD software solutions Capturing required knowledge Custom CAD data migration tools Custom tools for CAD data translation Data structuring in KBE Design process automation Engineering High-quality CAD data transfer Importance of medical device design IT-Services IT-Solution KBE KBE implementation issues Knowledge-Based Engineering challenges Marketing medical 3D printing Medical Design Software Medical device design Medical device design and development medical imaging software medical software development Neutral formats for CAD data conversion Patient-specific implants Process of CAD Automation Product Development Software Software development for medical devices Streamlined data migration process Successful CAD data migration What is automation design process? What is Design Process Automation