The healthcare industry is undergoing a significant transformation, and at the heart of this change is computer-aided design, or CAD. While CAD design has traditionally been linked to architecture and engineering, it now plays an integral role in healthcare, more specifically in designing of Medical Devices.

This technology has changed our perspective on developing and improving medical device design and equipment. It’s not just about precision; CAD is reshaping healthcare by promoting collaboration, personalizing solutions, ensuring safety, and making medical device manufacturing more cost-effective.

Learn more about how CAD is reshaping the healthcare landscape, making medical solutions safer, more efficient, and tailored to individual needs.

What is CAD in Medical Technology?

Computer-aided design, or CAD, is a transformative technology that has found a crucial application in medical technology. CAD involves computer software and advanced 3D modeling to design, visualize, and simulate various medical devices and equipment.

This technology has become the backbone of developing and improving medical solutions, enhancing precision, efficiency, and innovation in healthcare.

Improving Healthcare Through CAD Design For Medical Equipment

CAD design has become a game-changer in modern-day healthcare, creating safer and more effective medical equipment.

Here’s how CAD has revolutionized patient care:

- Precise and perfect: At its core, CAD design for medical devices excels in precision. In the context of medical technology, precision is of utmost importance. CAD allows for the meticulous design of every component of medical devices, ensuring that they meet exact specifications.

Whether it’s the dimensions of a surgical instrument or the intricacies of a diagnostic device, CAD delivers a level of precision that is indispensable to patient safety and treatment effectiveness.

- Fast testing and fixes: CAD design has accelerated healthcare innovation by enabling swift testing and design adjustments. With the power of virtual prototypes, designers can rigorously evaluate and fine-tune medical device concepts efficiently.

This approach facilitates the early detection of potential issues and allows for rapid modifications to the digital designs. As a result, the development cycle of medical equipment is significantly shortened, reducing the time it takes to transition from prototyping to commercialization.

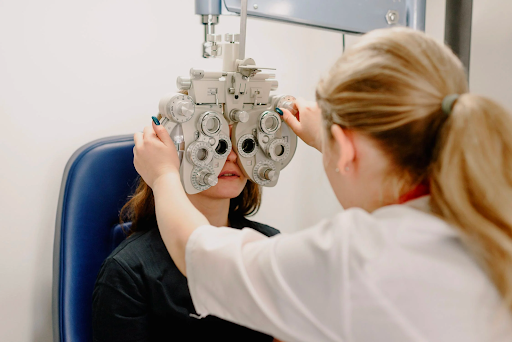

- Custom-made for patients: One of CAD’s standout features in medical technology is its capacity for customization. It acknowledges the diversity of medical conditions and patient needs. CAD for medical device design can be tailored to meet the unique requirements of individual patients.

This personalization extends to patient-specific implants, prosthetics, dental devices, and more. These custom-made devices result in improved patient outcomes and satisfaction.

- Teamwork and collaboration: Medical technology is a complex and multidisciplinary field. Developing innovative medical solutions necessitates collaboration among diverse experts, including medical professionals, engineers, and designers.

CAD design creates a collaborative hub where these interdisciplinary teams can converge. It provides a common language and platform for experts from different fields to collaborate, share their insights, and collectively contribute to creating groundbreaking healthcare solutions.

- 3D manufacturing: Integrating CAD design with 3D printing, also known as additive manufacturing, represents a game-changing advancement in medical technology. This combination facilitates the production of highly intricate and complex medical devices that are challenging to manufacture using traditional methods.

With its precision, CAD opens the door to innovative and highly detailed medical equipment that can significantly impact patient care and treatment.

Cost-Efficiency Through CAD

One of the most significant advantages of CAD is its ability to minimize the production cost of medical devices. This remarkable cost-efficiency is achieved through several key aspects, which save resources and contribute to the development of safer and more accessible healthcare solutions.

Let’s have a look:

- Streamlined prototyping: CAD reduces the cost of medical device prototyping. By creating detailed digital models, it reduces the need for expensive physical prototypes. This saves time and significantly reduces prototyping expenses, which can often be a substantial part of the production budget.

- Enhanced manufacturing efficiency: CAD software equips engineers with precise and comprehensive device models. This enhanced clarity and accuracy in design translate to a more efficient manufacturing process. Fewer errors and a streamlined workflow result in cost savings by minimizing the resources required to rectify mistakes.

- Material optimization: CAD offers engineers the tools to optimize the use of materials. This is especially crucial in producing medical devices involving substantial material costs. CAD contributes to significant savings by ensuring that material usage is efficient and minimal waste occurs.

- Early issue identification: A key cost-saving factor is the ability of CAD to identify and rectify potential design flaws before the manufacturing phase. This early issue identification ensures that costly errors in the production of medical devices are avoided, further reducing the overall cost of development.

- Improved quality control: CAD’s precision goes beyond cost savings; it also enhances the quality of medical devices. By detecting and addressing design flaws early, CAD ensures that the final product meets safety and quality standards, reducing the likelihood of costly recalls or post-production modifications.

Ensuring Safety with CAD for Medical Device Design

CAD design significantly enhances the safety of medical equipment by combining technological capabilities that work in harmony to minimize risks and ensure patient well-being.

With CAD’s transformative influence, medical device designers and healthcare entrepreneurs can embrace a more proactive and patient-centric approach to developing medical devices.

Here’s how CAD is reshaping the safety landscape in medical equipment design:

- Virtual safety net: CAD extends a virtual safety net over the entire design process. CAD design for medical equipment goes through exhaustive virtual testing before a single physical prototype is created. This involves subjecting the medical equipment to simulations and uncovering potential flaws or vulnerabilities in the design. This proactive approach ensures safety from the outset.

- Simulating real-world challenges: CAD software empowers designers to recreate real-world challenges that medical equipment may encounter. This includes rigorous stress tests, simulations of device interactions with patients, and even scenarios involving various environmental conditions. Through these simulations, designers can identify potential points of failure, addressing them before the equipment is produced.

- Personalized safety: CAD design enables the creation of patient-specific medical equipment. This means that devices are not only tailored to individual needs but are also designed to maximize safety and comfort for each patient. Customization minimizes the risk of discomfort or injury due to ill-fitting equipment.

- Ergonomics for safety: CAD incorporates ergonomics as a fundamental aspect. This means that not only are medical devices designed for optimal functionality but also with a focus on user-friendliness for healthcare professionals and patients. A more user-centric design reduces the chances of errors or accidents during usage.

- Early warning system: One of CAD’s most significant contributions to safety is its ability to detect design flaws or potential safety concerns early in development. Addressing these issues before production also minimizes the need for cost and time-intensive recalls and modifications.

Conclusion

As technology advances, we expect CAD design to play an indispensable role in the evolution of medical devices. The integration of CAD in the development of medical devices has shown remarkable promise in enhancing product innovation, precision, and efficiency. From enhancing surgical instruments to crafting custom implants, the impact of CAD design for medical devices is undeniable.

CADVision can be your partner in taking your medical device design process to the heights of operational efficiency. With intuitive 3D modeling tools, real-time collaboration capabilities, simulation and testing features, and seamless integration with 3D CAD modeling technology, CAD Vision empowers you to create safer, more innovative, and compliant medical devices.

What sets CADVision apart is the ability to deliver forward-thinking solutions, thanks to long-term client partnerships and a focus on innovation. CADVision offers tailored solutions that match customer needs and preferences by combining industry knowledge with the latest technology.

Choose CADVision today to shape a better tomorrow in healthcare technology!