Computer-aided design (CAD) has brought a significant shift to several branches of applied science, like automotive engineering, architecture, civil engineering, and mechanical engineering. The benefits of CAD software have now moved beyond the purview of engineering to take significant strides in medical technology.

With technological advancements happening in real-time, it is no surprise that the role of CAD systems in the field of medicine is expanding into new horizons.

From its application in manufacturing medical devices to its use in producing customized patient-specific implants, computer-aided design and computer-aided manufacturing (CAD/CAM) in healthcare have turned many medical wonders into reality. Whether clinical medicine, biomedical engineering, oral restructuring, tissue engineering, artificial limbs, or robotic surgery, CAD/CAM is redefining the medical industry.

This overview will explore the rising importance of CAD technology in healthcare and how it can become instrumental in offering precise, customized patient-specific solutions while reducing the chances of error.

How is CAD Used in Healthcare?

Computer-aided design allows medical professionals to create, modify, and analyze digital models of human physiologies, providing insight into each patient’s health. Using CAD/CAM in healthcare has helped enhance precision and efficiency in diagnosis and medical procedures and reduce complications and costs.

Here are some practical uses cases of CAD in medical technology, illustrating its transformative potential:

1. Precision Diagnosis and Imaging

Precision diagnosis is one of the foremost contributions of computer-aided design in the medical field.

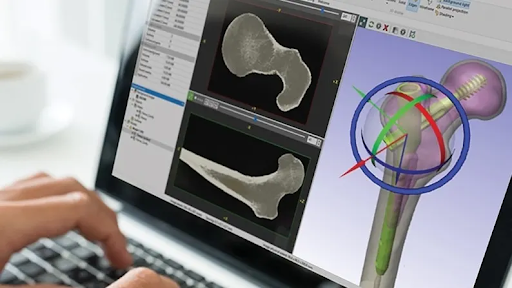

Integrating CAD systems with imaging devices like MRI and CT scan machines facilitates the creation of detailed, specific 3D models of patients’ organs and other anatomical parts. This helps healthcare professionals identify abnormalities accurately and decide on the best course of action. With the digital reconstruction of the area to be operated on, surgeons can plan the best approaches, minimizing the chance of unprecedented risks during surgery.

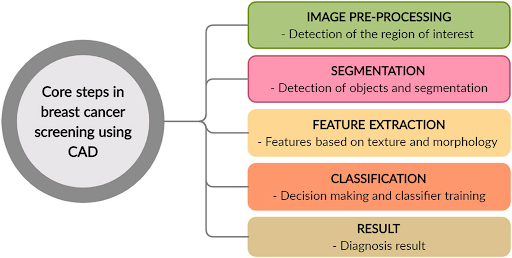

CAD has shown particular promise in detecting subtle anomalies in the context of cancer detection in imaging that can remain undetected in 2D images. With CAD, physicians can detect cancer early on, resulting in timely treatment and better prognosis. Surgeons can use CAD technology to gain precise information about the location, size, and characteristics of tumors or cancerous lesions. They use such insights as a guide to develop optimal treatment strategies.

2. Customized Treatment

CAD has ushered in an era of patient-specific personalized medicine, tailoring treatment plans and operative solutions to individual patient characteristics. By leveraging CAD software, medical professionals can optimize therapeutic interventions and services based on patients’ environmental, behavioral, and genetic data. This minimizes the probability of side effects and enhances treatment outcomes

Some instances of personalized medicine incorporating CAD systems include the creation of precise prosthetic limbs, dental implants, orthopedic implants, bioengineered heart valves and stents, cranial plates, and joint replacements.

Contrary to traditional implants, these perfectly match the patient’s anatomy, eliminating the need for post-surgical adjustments, enhancing functionality, and reducing the probability of immunological rejection. It also results in better long-term outcomes, significantly improving a patient’s quality of life.

Leverage our expertise in digital transformation and cutting-edge solutions to make your mark in the medical devices and diagnostics sector.

3. Surgical Planning and Simulation

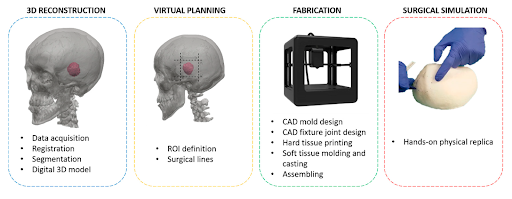

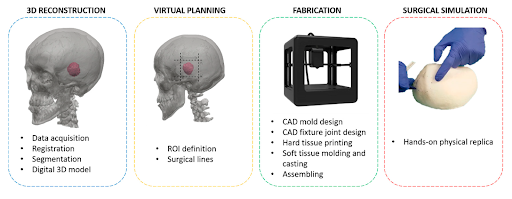

The most prominent impact of CAD in medical technology is in surgical planning and implementation. CAD helps surgeons recreate a 3D layout of patient-specific organs and other anatomical structures, facilitating them to explore all possible surgical scenarios. This fosters a deeper understanding of the patient’s unique anatomy.

For instance, in neurosurgery, which involves intricate, high-stakes procedures, CAD-driven simulations have been a blessing. Surgeons can now use virtual models to simulate complex brain surgeries, practicing complicated maneuvers and refining techniques before entering the operating room. This enhances the surgeon’s skill and confidence and contributes to better patient outcomes by minimizing the risk of complications.

4. Training and Education

The applications of CAD in medicine extend beyond research labs and operating rooms to cover medical education and training. It provides aspiring healthcare professionals with immersive learning experiences. CAD systems generate virtual simulations and anatomical models, offering a dynamic platform for trainees to hone their skills in a risk-free environment.

The integration of CAD-driven simulators has dramatically transformed surgical training. With realistic human physiology, anatomy, and pathology models, budding surgeons can practice their skills to build confidence in diagnosing and treating patients. This, in turn, accelerates their learning curve.

Simulations help patients see and understand their conditions and how a proposed treatment plan will assist them in healing.

5. Enhanced Communication and Collaboration

CAD systems promote interdisciplinary collaboration among healthcare professionals, fostering a more comprehensive approach to patient care. Through shared virtual models and collaborative platforms, medical teams can collectively analyze complex cases, share insights, and formulate comprehensive treatment plans.

Take, for example, an oncological case. Oncological cases often require the collaboration of multiple specialists from various disciplines. CAD facilitates multidisciplinary tumor board meetings where experts from different specialties collaboratively review patient cases.

By visualizing 3D models generated from imaging data, oncologists, radiologists, and surgeons can collectively assess the extent of tumor involvement, discuss treatment options, and make unanimous decisions, ensuring a holistic and patient-centric approach to cancer care.

6. Bioengineering and Research

Computer-aided design-based modeling techniques help researchers develop innovative biomedical models and devices like drug delivery systems, artificial organs, and biosensors. CAD software can even help bio-medical researchers conduct experiments and test hypotheses like tissue engineering, gene editing, nanotechnology, and more, all without running the risk of mounting expenses.

7. 3D Printing Medical Instruments and Devices

Computer-aided design-based modeling techniques help researchers develop innovative biomedical models and devices like drug delivery systems, artificial organs, and biosensors. CAD software can even help bio-medical researchers conduct experiments and test hypotheses like tissue engineering, gene editing, nanotechnology, and more, all without running the risk of mounting expenses.

These devices can be developed at a much lower cost by designing precise 3D models with appropriate measurements and specifications. In addition, 3D modeling helps spot potential issues in the early design phase, allowing them to be restructured accordingly, thus saving post-production redesigning costs.

Wrapping Up

The integration of CAD into the field of medicine presents a transformative shift, enhancing precision, innovation, and collaboration in healthcare. CAD has become an indispensable tool for medical professionals and surgeons — from precise diagnostics and personalized treatment planning to immersive surgical simulations and collaborative decision-making.

With advancing technology, the relationship between CAD and medicine will redefine patient care and reshape the future for a more precise and innovative healthcare system.

At CADVision, we are committed to offering you the most innovative, digitally transformative solutions in the medical, automotive, transportation, and other industries. Our smart product engineering services ensure our clients get modular, scalable, and configurable products with optimal operational efficiency. Our experts can guide you in every step of the product development process — software, mechanical, compliance, and quality.

Popular Posts

- What Are the 5 Key Aspects of Medical Device Design?by Admin

- Latest Trends in Design Process Automationby Admin

- Generative AI Revolutionizing Medical Device Innovationby Admin

- How to Design & Develop Custom-Specific Implantsby Admin

- Key Considerations for Planning a Successful Design Process Automation Strategyby Admin

Categories

Tags

3D printing help in the medical field Automation in CAD data migration Business CAD customization services CAD data migration benefits CAD data migration methods CAD data migration planning CAD design automation CAD Design Automation In Medical Implants CAD development services CAD for Medical Device Design CAD Software CAD software development CAD software development companies CAD software solutions Capturing required knowledge Custom CAD data migration tools Custom tools for CAD data translation Data structuring in KBE Design process automation Engineering High-quality CAD data transfer Importance of medical device design IT-Services IT-Solution KBE KBE implementation issues Knowledge-Based Engineering challenges Marketing medical 3D printing Medical Design Software Medical device design Medical device design and development medical imaging software medical software development Neutral formats for CAD data conversion Patient-specific implants Process of CAD Automation Product Development Software Software development for medical devices Streamlined data migration process Successful CAD data migration What is automation design process? What is Design Process Automation

Leverage our expertise in digital transformation and cutting-edge solutions to make your mark in the medical devices and diagnostics sector.

3. Surgical Planning and Simulation

The most prominent impact of CAD in medical technology is in surgical planning and implementation. CAD helps surgeons recreate a 3D layout of patient-specific organs and other anatomical structures, facilitating them to explore all possible surgical scenarios. This fosters a deeper understanding of the patient’s unique anatomy.

For instance, in neurosurgery, which involves intricate, high-stakes procedures, CAD-driven simulations have been a blessing. Surgeons can now use virtual models to simulate complex brain surgeries, practicing complicated maneuvers and refining techniques before entering the operating room. This enhances the surgeon’s skill and confidence and contributes to better patient outcomes by minimizing the risk of complications.

4. Training and Education

The applications of CAD in medicine extend beyond research labs and operating rooms to cover medical education and training. It provides aspiring healthcare professionals with immersive learning experiences. CAD systems generate virtual simulations and anatomical models, offering a dynamic platform for trainees to hone their skills in a risk-free environment.

The integration of CAD-driven simulators has dramatically transformed surgical training. With realistic human physiology, anatomy, and pathology models, budding surgeons can practice their skills to build confidence in diagnosing and treating patients. This, in turn, accelerates their learning curve.

Simulations help patients see and understand their conditions and how a proposed treatment plan will assist them in healing.

5. Enhanced Communication and Collaboration

CAD systems promote interdisciplinary collaboration among healthcare professionals, fostering a more comprehensive approach to patient care. Through shared virtual models and collaborative platforms, medical teams can collectively analyze complex cases, share insights, and formulate comprehensive treatment plans.

Take, for example, an oncological case. Oncological cases often require the collaboration of multiple specialists from various disciplines. CAD facilitates multidisciplinary tumor board meetings where experts from different specialties collaboratively review patient cases.

By visualizing 3D models generated from imaging data, oncologists, radiologists, and surgeons can collectively assess the extent of tumor involvement, discuss treatment options, and make unanimous decisions, ensuring a holistic and patient-centric approach to cancer care.

6. Bioengineering and Research

Computer-aided design-based modeling techniques help researchers develop innovative biomedical models and devices like drug delivery systems, artificial organs, and biosensors. CAD software can even help bio-medical researchers conduct experiments and test hypotheses like tissue engineering, gene editing, nanotechnology, and more, all without running the risk of mounting expenses.

7. 3D Printing Medical Instruments and Devices

This is the most frequently used application of CAD technology in healthcare. Designing and developing medical equipment is a cost-intensive and exhaustive process. It requires creating multiple complex, individual components before assembling them to build the finished product.

These devices can be developed at a much lower cost by designing precise 3D models with appropriate measurements and specifications. In addition, 3D modeling helps spot potential issues in the early design phase, allowing them to be restructured accordingly, thus saving post-production redesigning costs.

Wrapping Up

The integration of CAD into the field of medicine presents a transformative shift, enhancing precision, innovation, and collaboration in healthcare. CAD has become an indispensable tool for medical professionals and surgeons — from precise diagnostics and personalized treatment planning to immersive surgical simulations and collaborative decision-making.

With advancing technology, the relationship between CAD and medicine will redefine patient care and reshape the future for a more precise and innovative healthcare system.

At CADVision, we are committed to offering you the most innovative, digitally transformative solutions in the medical, automotive, transportation, and other industries. Our smart product engineering services ensure our clients get modular, scalable, and configurable products with optimal operational efficiency. Our experts can guide you in every step of the product development process — software, mechanical, compliance, and quality.